GET A FREE QUOTE

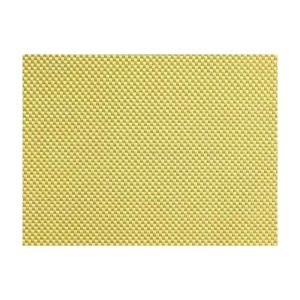

Para Aramid Pulp

Kevlar pulp for brake pad and gasket

KARAMID® aramid pulp is widely used in brake pads and gaskets as friction and sealing material, increasing its wear-resistance and service life significantly.

Aramid pulp is produced by a series process of cutting, grinding and suspending in water. The aramid fiber is fibrillated into pulp. The pulp not only inherits the high-strength, high-modulus, high-temperature resistance, abrasion resistance and excellent chemical stability from para-aramid fiber, but also has high dispersibility, specific surface area and grip force to provide reinforcement and viscosity control under shear stress.

Features

- Versatile and adjustable

- High fibrillation

- Improves heat and chemical resistance

- Reduces product brittleness

Main Application

|

|

|

|

|

STORAGE

KARAMID® para-aramid pulp should be kept dry in original bags and properly stocked.

Preferably store at room temperature with 35-65% relative humidity.

Avoid the sun, rain and fire.

PACKAGING

Net weight: 5kg per bag